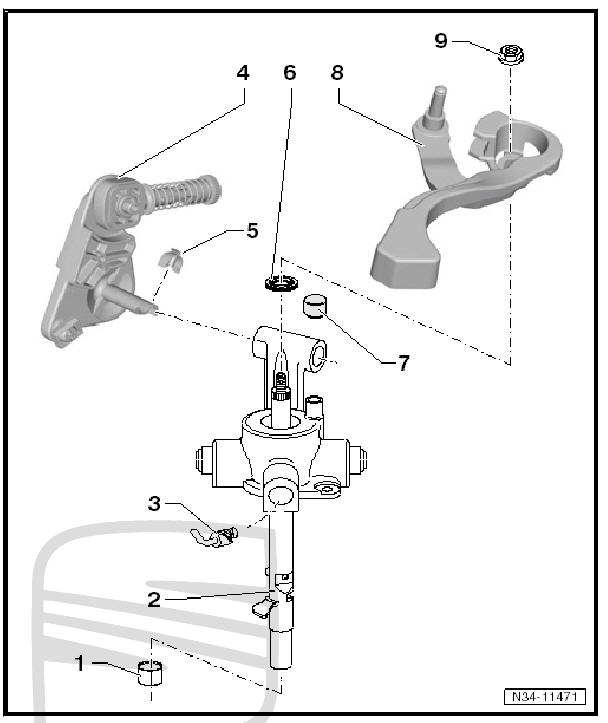

Seat Leon >> Assembly overview - selector unit

SEAT Leon Service and Repair Manual / 5-speed manual gearbox 0AH / Controls, housing / Gearbox: disassembly and assembly / Assembly overview - selector unit

Note

- Lubricate bearing positions and sliding surfaces.

- For grease allocation, refer to - Electronic parts catalogue (ETKA) .

- - Shift collar

- For the gear selection shaft

- Press out

- Press on

- - Selector shaft with cover

- Renew together

- Removing and installing

- - Angled rod

- For adjusting selector mechanism

- Removing

- Press on

- - Gate relay lever

- Installation position

- - Clip

- - Oil seal

- Replace after removal

- - Cap

- For gearbox breather

- - Gear selection rod

- Illustration may deviate from genuine part

- Position so that the teeth free area is inserted on the selector shaft

- Can be replaced with the gearbox drive mechanism in place

- Installation position

- - Hexagon nut

- Self-locking

- Must be renewed if removed

- 23 Nm

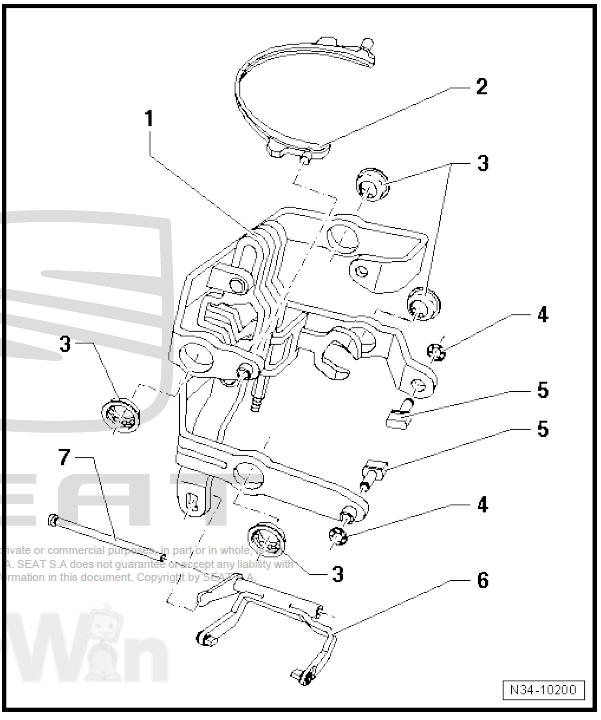

Assembly overview - input shaft, output shafts, differential, selector rods

- - Differential:

- Dismantling and assembling

- - Gearbox housing

- Repairing

- - Oil drain plug

- Tightening torque

- - Flanged shaft with pressure

spring

- Removing and installing

- Assembling

- - Conical bolt

- Tightening torque

- - Bolt

- For securing the bearing mounting for input and output shafts.

- Self-locking

- Must be renewed if removed

- 5 Nm and turn 90º further

- - Hexagon flange nut

- For the gear selection mechanism.

- Self-locking

- Must be renewed if removed

- 23 Nm

- - O ring

- Must be renewed if removed

- - Bearing shaft

- - Bolt

- Must be renewed if removed

- 5 Nm and turn 90º further

- - Selector shaft with cover

- (Selector unit)

- Removing and installing

- Repairing

- - Bolt

- Must be renewed if removed

- 5 Nm and turn 90º further

- - Bolt

- 6 Nm

- - Gearbox neutral position sender - G701-

- For vehicles with start stop system

- - Reversing light switch - F4-

- Switch without sealing ring: if necessary clean thread of the switch

- Switch without sealing ring: if necessary install with sealant

- Allocate the sealant via the - Electronic parts catalogue (ETKA)

- Switch with undetachable sealing ring: replace switch

- Switch with separate seal: replace sealing ring

- Lightly coat lug with MoS2 grease

- Renewing with gearbox installed: removing noise insulation

- 20 Nm

- - Oil seal

- Not fitted in all gearboxes

- Must be renewed if removed

- - Selector mechanism

- (Gear change prongs)

- Repairing

- - Input and secondary shafts with allotment/grooved ball bearings

- If bearing mounting is separated from gearbox housing, then mounting must always be renewed.

- Remove and press on bearing mounting

- Disassembly and assembly of the input shaft

- Dismantling and assembling output shaft

- - Reverse gear shaft

- - Reverse gear wheel

- - Bolt

- Must be renewed if removed

- To fasten reverse gear pinion axis

- 25 Nm and turn 45º further

- - Oil collector

- - Magnet

- - Oil guide

Assembly overview - selector forks

Note It is not necessary to dismantle the selector fork group in order to dismantle and assemble selector segments, lock washers and angular contact ball bearings.

- - Selector fork group with selector plate

- - 3rd/4th gear base strip

- Identification

- After installation, selector segment must still rotate freely

- - Ball bearing

- 4x

- Removing

- Press inner race into outer race

- Installing

- - Retainer

- Must be renewed if removed

- Removing

- Installing

- - 1st/2nd gear selection

group

- Identification

- After lock washer is installed, segment must still rotate freely

- Selector fork with selector segment

- - 5th gear selector fork with

selector segment

- Selector segment is permanently connected to selector fork.

- Identification

- - Bearing shaft

- For 5th gear selector fork.

Gearbox: disassembly and assembly

Gearbox: disassembly and assembly

Removing and installing gearbox housing cover, clutch housing,

selector shaft with selector mechanism cover, input shaft, output

shaft, differential and selector mechanism.

Special tools and worksh ...

Repair selector forks

Repair selector forks

Special tools and workshop

equipment required

Tightening plate - VW 402-

Thrust pad - 3290/1-

Assembly tool - 3301-

Thrust pad - VW 431-

Spacer sleeve - VW 472/2-

Assembly mandrel - 1 ...

See also:

Exploded view of bumper cover

Rear bumper trim, three and five-door models: exploded view

- Tight spreader block

5 off

DANGER!Risk of ingress of exhaust

fumes in the passenger

compartment

Tak ...