Seat Leon >> Removing and installing wheel bearing housing

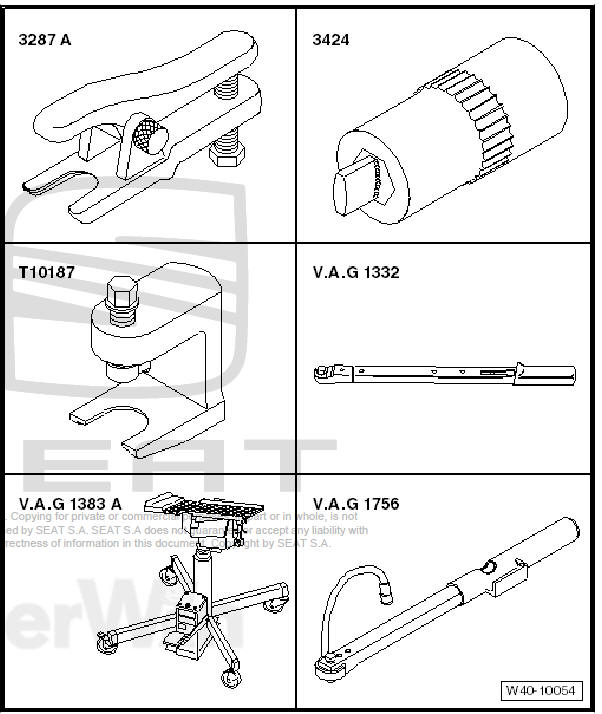

Special tools and workshop equipment required

- Ball joint puller - 3287A-

- Spreader - 3424-

- Ball joint puller - T10187-

- Torque wrenches - V.A.G 1332-

- Engine elevator - V.A.G 1383 A-

- Rotation angle spanner - V.A.G 1756-

Removing

- Remove bolt for drive shaft.

| Caution Wheel bearings must not be subjected to load after loosening bolt securing drive shaft at wheel hub. If they have to support the weight of the vehicle they will be damages and their service life will be reduced. It is not permissible to turn drive shaft bolt more than 90º anticlockwise if vehicle is standing on its wheels. Do not attempt to move the vehicle without the drive shafts fitted; this would result in wheel bearing damage. If it is necessary for a vehicle to be moved, please comply with the following instructions:

|

- Remove front wheel on affected side.

- Remove the ABS speed sensor.

- Remove brake disc.

- Detach bracket for brake line and electrical wiring from wheel bearing housing and move clear.

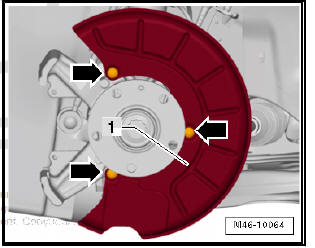

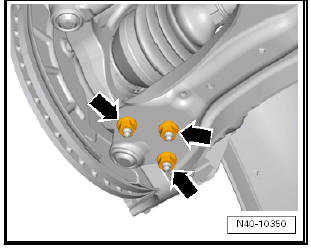

- Remove splash plate -1- from wheel bearing housing -arrows-.

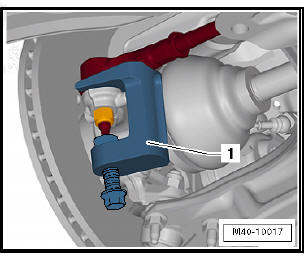

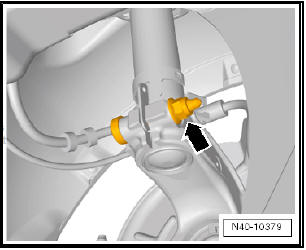

- Loosen nut on track rod ball joint but do not remove completely.

- Press track rod off wheel bearing housing using ball joint puller - T10187- -1-.

| Caution Leave nut screwed several turns onto track rod ball joint shank to protect thread. |

- Unscrew nut, and remove track rod upwards from wheel bearing housing.

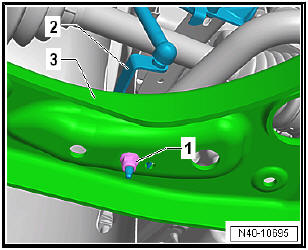

Vehicles with vehicle level senders

- Remove nut -1-.

- Pull bracket -2- for front left vehicle level sender - G78- and/or for front right vehicle level sender - G289- out of suspension link -3-, as applicable

Continuation for all models:

- Unscrew nuts -arrows-.

- Pull swivel joint out of suspension link.

- Pull outer joint of drive shaft out of wheel hub.

- Secure drive shaft to body with wire.

- Position engine and gearbox jack - V.A.G 1383 A- under wheel bearing housing.

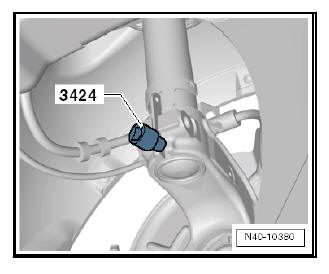

- Remove the threaded steering knuckle/suspension strut union -arrow-.

- Fit Separator device - 3424- in the steering knuckle groove.

Note Make sure that the spreader - 3424- is only inserted into the wheel bearing housing. Insert sufficiently to ensure that the metal tab of the suspension strut is not damaged.

- Turn ratchet handle through 90º and detach from spreader - 3424- .

- Pull wheel bearing housing from suspension strut.

Note If wheel bearing housing is renewed, swivel joint must be transferred.

New nuts must be used for this purpose.

Installing

Carry out installation in the reverse sequence, noting the following:

Note

- Lever on vehicle level sender must face towards outside of vehicle.

- Thread of vehicle level sender must be screwed into outer hole in suspension link. Retaining lug for vehicle level sender must engage in inner hole in order to guarantee correct installation position.

- On vehicles with vehicle level sender, carry out basic settings for wheel damper electronics - Vehicle diagnostic tester.

Specified torques

- Screw for speed sender .

- Bolts for splash plate, brake caliper, brake disc .

Wheel bearing unit

Wheel bearing unit

Assembly overview - wheel bearing

- Cover plate

- Bolt

12 Nm

- Wheel bearing unit

Removing and installing

Cannot be repaired

- Bolt

Always renew after removing

L ...

Removing and installing wheel bearing

unit

Removing and installing wheel bearing

unit

Special tools and workshop equipment required

Torque wrenches - V.A.G 1332-

Removing

Remove bolt for drive shaft

CautionWheel bearings must not be subjected to load

after lo ...

See also:

Repair notes

Repair work on refrigerant circuit which

may only be performed in appropriate

workshops by specially trained mechanics

Repair work on refrigerant circuit which

may be performed only in appropriate ...