Seat Leon >> Lowering subframe

Special tools and workshop equipment required

- Engine elevator - V.A.G 1383 A-

- Torque wrenches - V.A.G 1332-

Removing

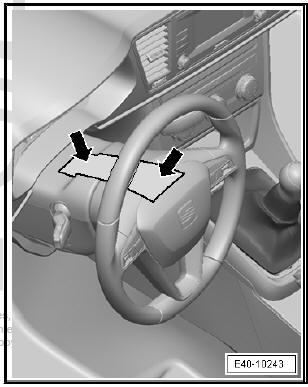

- Turn steering wheel to straight-ahead position and remove ignition key so that the steering lock engages.

- To prevent unintentional turning, secure steering wheel in straight-ahead position with adhesive tape -arrow-.

Note

- Only use adhesive tape that can be completely removed afterwards without leaving marks.

- Do not turn steering wheel while performing repair work, as otherwise airbag coil connector and return ring with slip ring - F138- could be damaged.

Vehicles with keyless locking and starting system "Keyless Access"

- Switch off ignition and open driver's door so that the steering lock engages.

Continuation for all models:

- Disconnect battery.

For left-hand drive models only

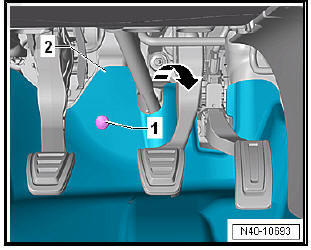

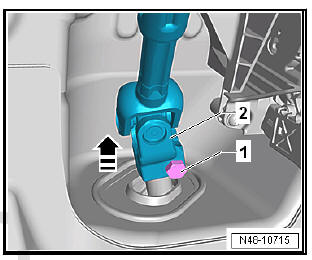

- Unscrew bolts -1- and fold footwell trim -2- in -direction of arrow- into the vehicle interior.

For right-hand drive models only

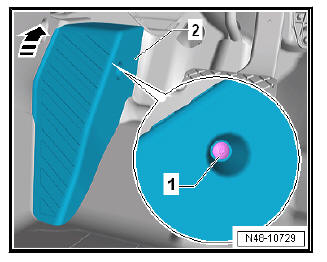

- Unscrew bolt -1-.

- Push foot support -2- upwards in -direction of arrow- and remove.

- Fold floor covering to the rear.

Continuation for all models:

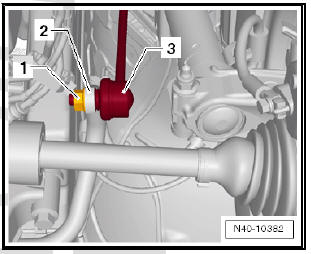

- Unscrew bolt -1- from universal joint -2- and pull off universal joint in -direction of arrow-.

| Caution The following work must not be performed while the universal joint is separated from the steering rack:

Not adhering to these instructions will result in irreparable damage. |

- Remove lower noise insulation.

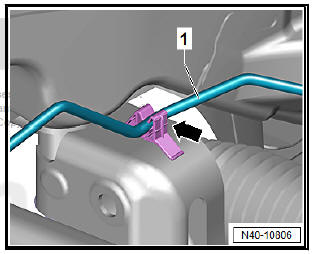

For vehicles with natural gas engines

- Detach natural gas line -1- from clip -arrow-.

Continuation for all models:

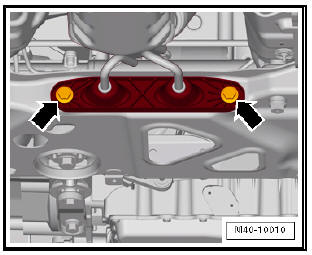

- Detach exhaust system bracket from subframe -arrows-

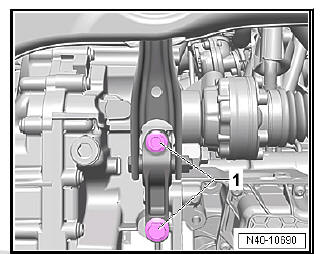

- Remove bolts -1- for pendulum support.

- Remove nut -1- from coupling rod -3- (left and right sides).

- Pull out coupling rod -3- from anti-roll bar -2- on left and right side.

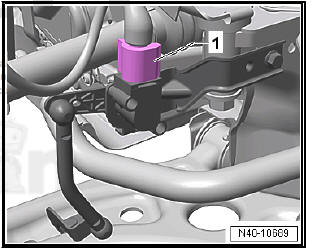

Vehicles with vehicle level senders

- Disconnect connector -1- on front left vehicle level sender - G78- and/or front right vehicle level sender - G289- , as applicable.

Continuation for all models:

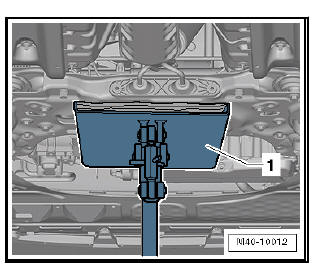

- Position engine and gearbox jack - V.A.G 1383 A- -1- under subframe.

- Fixing subframe and lowering approx. 10 cm.

Note Important: Take care to avoid overstretching the electrical wiring for the steering and the oil level and oil temperature sender - G266- .

Installing

Carry out installation in the reverse sequence, noting the following:

Note

- Coat seal on steering box with suitable lubricant, e.g. soft soap, before installing steering box.

- After fitting the steering box to the universal joint ensure that

the seal is not kinked against the assembly plate on the steering

box. The opening to the footwell must seal correctly.

Otherwise, noise or water may enter.

- Ensure sealing surfaces are clean.

- Removing locating pins - T10486/1-.

- On vehicles with vehicle level sender, carry out basic settings for wheel damper electronics - Vehicle diagnostic tester.

Specified torques

- Bolts for pendulum support.

- Bolts for noise insulation .

- Exhaust system to subframe .

If even when using locating pins - T10486/1- a crooked steering wheel is determined during the road test, carry out a wheel alignment check. In this case the wheel alignment test results must be archived in the vehicle files.

Secure the subframe

Secure the subframe

Note

Certain repairs on vehicles require the removal of the subframe

or the entire front axle.

The original position of the subframe relative to the body can

be retained with the aid of qty. ...

Suspension strut, upper suspension

link

Suspension strut, upper suspension

link

Assembly overview - suspension strut, upper suspension link

- Spring seat

Check fitting position

- Shock absorber

Different versions possible.

- Bolt

Always renew after ...

See also:

Front camera for assist systems

Assembly overview - Front camera for assist systems

- Cover

- Front camera for driver assist

systems - R242-

Removal and installation

- Lens Hood

With pane heating

Removal a ...