Seat Leon >> Differential: assembly and disassembly

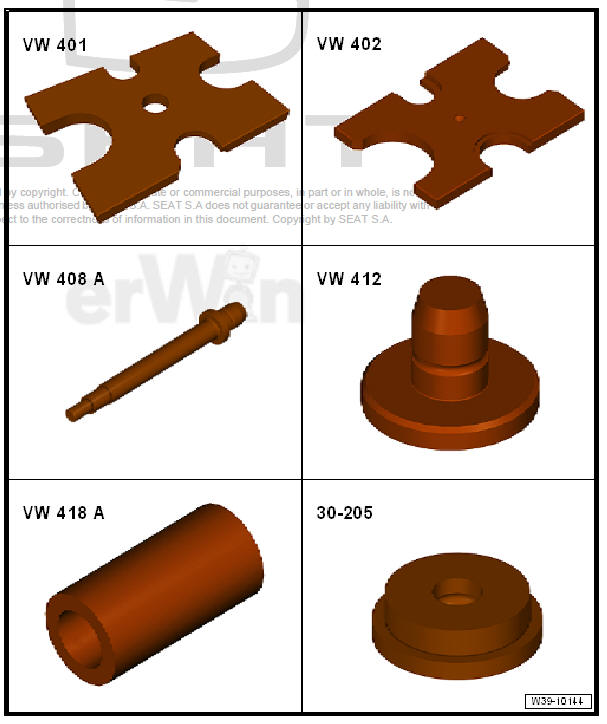

Special tools and workshop equipment required

- Tightening plate - VW 402-

- Tightening plate - VW 401-

- Die - VW 408 A-

- Die - VW 412-

- Tube element - VW 418 A-

- Thrust plate - 30-205-

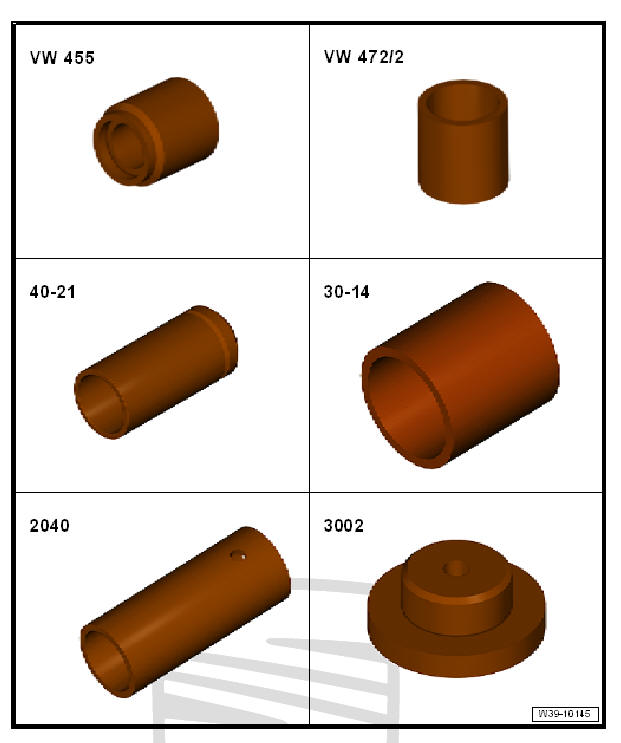

- Drift sleeve - VW 455-

- Spacer sleeve - VW 472/2-

- Inlay socket - 40-21-

- Tube for releasing - 30-14-

- Tube element - 2040-

- Thrust pad - 3002-

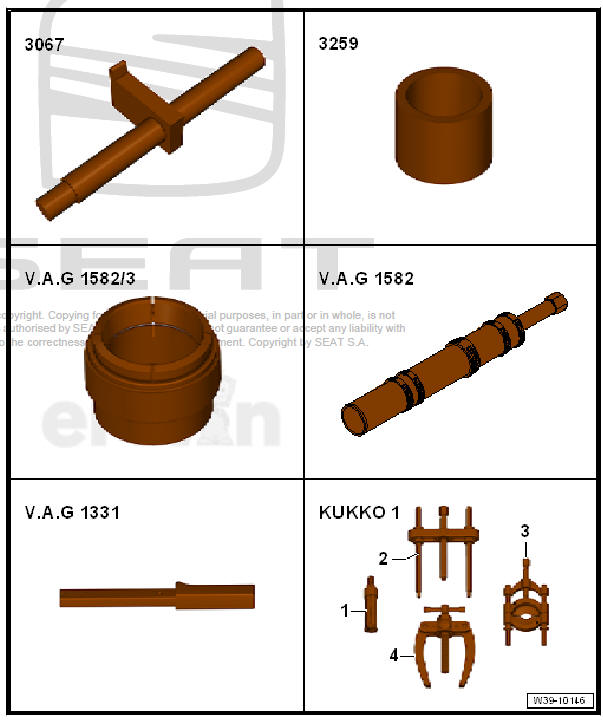

- Counterhold - 3067-

- Pipe - 3259-

- Tapered roller bearing puller - V.A.G 1582-

- Locking device - V.A.G 1582/3-

- Not suitable: tools 1-4

- Internal puller - VAS 251 615- or, e.g. internal puller - Kukko 21/7-

- Counter-support - VAS 251 623- or, e.g. counter-support - Kukko 22/2-

Note

- Heat the inner ring of the roller bearing to 100 ºC before fitting.

- Replace both conical roller bearings together.

- If tapered roller bearings, differential cage, gearbox housing or clutch housing is renewed, adjust differential.

Remove the outer ring of the roller bearing from the gearbox casing

- - Counter-support - VAS 251 623- or, e.g. counter-support - Kukko 22/2-

- - Internal puller 46...58 mm - VAS 251 615- or, e.g. internal puller - Kukko 21/7-

Pressing tapered roller bearing outer race into gearbox housing

- Support the gearbox casing by fitting the tube - 3259- directly underneath the bearing allotment.

Remove the inner ring and roller bearing unit

Note Both tapered roller bearing inner races are pulled off the differential cage in the same way.

Drive in the inner ring and conical roller bearing unit

- Support inner race on opposite side using installing sleeve - VW 455- .

Shoulder of installing sleeve - VW 455- faces towards differential cage.

Note Both tapered roller bearing inner races are pressed onto the differential cage in the same way.

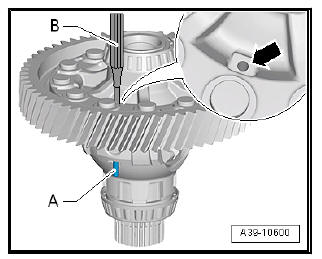

Press the outer ring of the tapered roller bearing -A- out of the clutch casing

B - Internal puller - VAS 251 615- or, e.g. internal puller - Kukko 21/7-

- Clamp internal puller firmly under tapered roller bearing outer race.

Insert the outer ring of the roller bearing into the clutch casing

Arrangement of differential cage to remove and install the clamping sleeve

- Check the hole for spring pin in differential cage.

| Bore | Length of spring pin (mm) |

Shoe steady pin |

|

| -A- | 24.0 (short spring pin) | Removing | Installing |

| -A- and -B-: | 36.0 (long spring pin) | Removing | Installing |

| Continuous | 36.0 (long spring pin) | Removing | Installing |

Press out differential pinion pin and shear off clamping sleeve

The spring pin is sheared off when pressing out.

- Remove the remaining piece of clamping sleeve out of the differential cage.

Remove the long clamping sleeve to remove the differential pinion pin

- Drive clamping sleeve -A- with a drift -B- diameter 5 mm out of bore -arrow-in the differential cage.

Note If there is no bore -arrow- in the differential cage, shear the clamping sleeve off.

Fitting sun gear and planetary gears

- Fit the complete assembly of thrust washers lubricating with gear oil.

- Install both sun wheels and secure (e.g. with flange shaft).

- Insert planet pinions offset 180º and pivot into position.

- Press the planetary gear shaft -arrow A- to the first small planetary gear.

- Place threaded pieces - arrows B - in the sun gears.

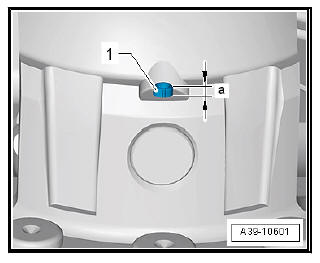

Installing spring pin for differential pinion pin

- Align hole in differential pinion pin with hole in differential cage.

- Drive in the clamping sleeve -1- with a drift to the dimension -a- = 2.5 mm.

- The clamping sleeve -1- must not touch the clutch housing.

Assembly overview - differential

Assembly overview - differential

- Conical bolt

Must be renewed if removed

25 Nm

- Right-hand articulation

flange

- Flanged shaft compression

spring

Fit behind the flanged

shafts

- Attack washer ...

Differential: Adjust

Differential: Adjust

Special tools and workshop

equipment required

End dimension plate - VW 385/17-

Universal dial gauge bracket - VW 387-

Tightening plate - VW 402-

Tightening plate - VW 401-

Die - VW 408- ...

See also:

Switching off the engine

– Stopping the engine.

– Turn the ignition key to position fig. 115 0.

After the engine is switched off the radiator fan may run on for up to 10

minutes, even if the ignition is switched ...