Seat Leon >> Dismantling and assembling output shaft

Special tools and workshop equipment required

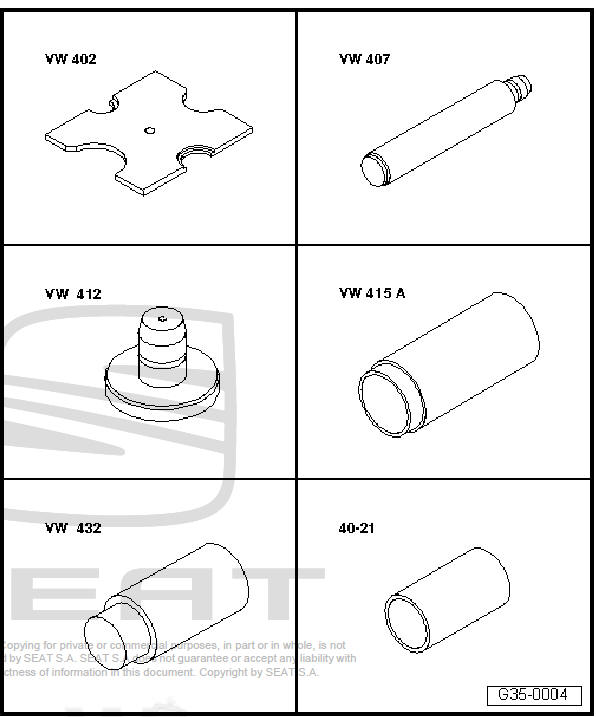

- Tightening plate - VW 402-

- Die - VW 407-

- Die - VW 412-

- Tube element - VW 415 A-

- Thrust pad - VW 432-

- Inlay socket - 30 - 100-

- Internal puller - VAS 251 611- or, e.g. internal puller - 1- Kukko 21/5-

- Counter-support - VAS 251 621- or, e.g. counter-support - Kukko 22/1-

- Counter-support - VAS 251 621- or, e.g. counter-support - Kukko 22/1-

Pulling cylindrical roller bearing out of clutch housing

- When pulling out, squeeze together retaining ring -arrow- of cylindrical roller bearing, using pliers -C-.

- - Counter-support - VAS 251 621- or, e.g. counter-support - Kukko 22/1-

- - Internal puller - VAS 251 611- or, e.g. internal puller - Kukko 21/5-

Extract the roller bearing from the clutch housing

- Support gearbox housing with tube - VW 415 A- (not visible in figure) directly below bearing support.

- When pressing in, compress circlip -arrow- for roller bearing using pliers -A-.

- Remove the pliers before the bearing is in its final installation position. The securing ring should insert into the groove of the clutch pan.

Press out securing ring -1- from its slot

- - Protective gloves

| WARNING Ensure retaining ring does not spring out uncontrolled. |

Press out the mobile sleeve / synchroniser body of 1st and 2nd gear

- After removing retaining ring, press off synchromeshed gear for 2nd gear together with locking collar and synchro-hub.

Installation position of 3rd gear and 4th gear

- Fit 4th gear wheel -A- onto output shaft.

Installation position:

The collar -arrow 1- should face towards the 3rd gear pinion -B-.

- Fit the securing rings -2- and -3-.

- Fit 3rd gear wheel -B- onto output shaft.

Installation position:

The collar -arrow 2- should face towards the 4th gear pinion -A-.

- Fit the securing ring -1-.

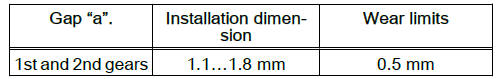

Check overall whether synchro-ring of the 1st and 2nd gear and inner ring are worn

- Press synchro-ring, outer race and inner ring onto cone of synchromeshed gear and measure gap -a- at three points displaced by approx. 120º using feeler gauge.

- Make a note of average value.

Note Always replace inner ring, outer ring and synchro-ring together.

Installation position of the outer, inner and synchromesh rings for 2nd gear

- Fit the interior ring -A- onto the mobile pinion for 2nd gear.

Angled lugs -arrow 1- face outer ring -B-.

- Fit the outer ring -B-.

Lugs -arrow 2- engage in notches -arrow 3- of synchromeshed gear.

- Fit the synchroniser ring -C-.

The recesses -arrow 4- locate on the tabs -arrow 1- of the inner ring -A-.

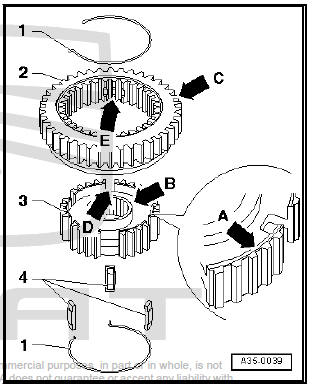

Disassembly and assembly of the mobile element/synchroniser body for the 1st and 2nd gear

- - Spring

- - Mobile element

- - Synchromesh hub

- - Locking element

- The locking collar is fitted onto the synchro-hub.

Installation position:

After assembling the unit, the groove of the front part -arrow Aand the highest collar -arrow B- of the synchro-hub should face the exterior cogs of the locking collar -arrow C-.

The deeper grooves -arrow D- of the locking piece in the synchromesh must be aligned with the grooves -arrow E- of the mobile sleeve.

Assembling locking collar with synchro-hub for 1st and 2nd gears

- Locking collar has been pushed over synchro hub.

- Fit the locking elements in the deepest grooves -arrows- and fit the elastic rings off-set by 120º. Angled end of spring must locate in hollow locking piece.

Insert mobile element/synchroniser body of the 1st and 2nd gear

Installation position:

Groove in locking collar for selector fork faces 1st gear and teeth for reverse gear face 2nd gear.

- Turn the synchromesh ring so that the notches coincide with the locking elements.

Fitting retaining ring

- Fit the 1st gear securing ring on the mobile sleeve / synchromesh assembly.

Installation position of outer ring for 1st gear

The tabs -arrows- point towards the teeth of the reverse gear -A-.

Installation position of 1st gear inner ring -A-

The tabs -arrows 1- insert into the recesses -arrows 2- of the synchromesh ring -B-.

Installation position of synchromeshed gear for 1st gear

The highest collar -A- should face 2nd gear -B-. Notches in shoulder -arrows- engage in lugs of outer ring (-arrow-)

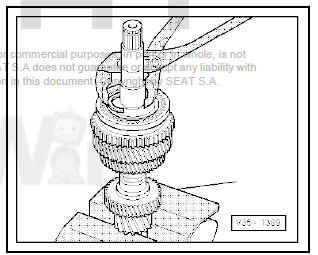

Assembly overview - output shaft

Assembly overview - output shaft

Note

When installing new gears or new input shaft, refer to - Electronic

parts catalogue (ETKA) and technical

data.

Install all bearings, synchromeshed gears and synchro-rings on output

...

See also:

Removing and installing battery tray

Removing and installing the battery support,

Version 1

Removing

Remove battery.

Remove air filter housing Engine.

Engine 2.0 l TDI CR

Engine 1.6 l TDI CR

Remove air filter housing ...