Seat Leon >> Matching wheels and tyres

General information

When radial or lateral runout of the wheel and tyre coincide, the imbalance of the wheel is amplified by the tyre.

For technical reasons, 100% true running is not possible.

Before match mounting the used wheels which are fitted on the vehicle, run the tyres warm. By doing this you will eliminate any existing flattening.

Match balancing process

- Let air out of tyre.

- Press tyre beads off wheel rim flanges.

- Apply tyre assembly paste all round the tyre beads.

- Rotate tyre by 180º in relation to disc wheel.

- Pump up tyre to approx. 4 bar.

- Attach the wheel (together with tyre) to the wheel balancing machine.

- Check wheel for true running and for radial and lateral runout .

Note

- If the theoretical values for radial and axial run-out are not exceeded, the wheel can be balanced to 0 grammes.

- If the radial and lateral runout is not within the specifications, the tyre must be rotated again.

- Let air out and press tyre beads off the wheel rim flanges.

- Rotate tyre by 90º in relation to disc wheel (quarter of a turn).

- Pump up tyre again to 4 bar and check true running.

Note

- If the theoretical values for radial and axial run-out are not exceeded, the wheel can be balanced to 0 grammes.

- If the theoretical values for radial and /or axial run-out are still exceeded, proceed as follows.

- Press tyre off wheel rim flange again as described above.

- Turn the tyre by 180º (1/2 turn) with respect to the rim.

If the radial and/or lateral runout are still not within the specified values, check the disc wheel for radial and/or lateral runout:

If the measured values for radial and lateral run-out of the wheel are within the specified values, the tyre has an impermissibly high radial or lateral run-out. In this case, the tyre must be renewed.

Note As assembly paste has been used between the tyres and the contour of the wheel rim during the assembly of the wheel, acceleration and sharp braking should be avoided for the first 100 to 200 km. Otherwise the tyre may spin on the wheel rim and all the above work will have been in vain.

Determining flat spots on tyres

What is flattening? Flattening is also known as flattening out .

Flattening out may cause imbalance when driving, as does a poorly balanced wheel. It is essential to recognise flattening of the tyre band as such.

Flattening cannot be balanced. It may reappear for different reasons at any moment. Complex tools are needed to remedy this, assuming a flat spot due to sudden braking.

Note Flattening as a result of braking can not be repaired. Tyres damaged in this way should be replaced.

Reasons for flattening

- The vehicle is left standing for several weeks without being used.

- The tyre pressure is too low.

- After being painted, the vehicle was left in the drying kiln of the painting workshop.

- The vehicle was parked while the tyres were hot in a cold garage or similar place for a long period of time . In this case, flattening may even occur overnight.

Solutions in the event of flattening

- The flattening out of tyres can not be corrected using workshop tools.

- This flattening out can only be removed by driving on the tyre until it warms up.

- The method described below is not recommended in cold and wintry weather.

Requirements/conditions

- If necessary, check tyre pressure and correct.

- If possible, drive the vehicle onto a motorway.

- Traffic and road conditions permitting, drive a 20- to 30-kilometre stretch at a speed of 120 to 150km/h.

WARNING

|

- Jack up the vehicle immediately after the trip.

- Unbolt wheels from vehicle.

- Balancing wheels on stationary wheel balancer.

Lateral deviation: verification

Points to check before and during the test drive:

- Check for possible damage to suspension components of the front and rear axles.

- Check tyre pressure.

- Check tyres visually for exterior damage, punctures, cuts, bulging sides, flattening and/or damage to the tread.

- Ask the client whether there have been any flat tyres which were repaired in a workshop; replace the tyre if necessary;

- Check tyres for uniform wear and tread depth.

- Check all the tyres are the same type, make and have the same tread pattern.

- If the tyres do not have a stipulated rotation direction, check whether the tyre DOT markings are on the outside. If not, the rims / tyres have been previously interchanged;

- The road surface should be straight and flat, without lateral cambers or dips.

- Carry out the test drive in the company of client, following the above-mentioned points (the client should drive in order to demonstrate the complaint).

Note The test can not be carried out in the event of strong side winds

If the complaint is justified, the wheel rims / tyres should be interchanged as described below: Before commencing, the following instructions should be observed.

Otherwise, the work may be carried out in vain

Note

- Mark the wheels / tyres before interchanging for the first time, for example with LF, RF, LR and RR.

- After interchanging the wheels or turning the tyre on the wheel rim, the performance of the vehicle should be checked on a test drive. Make a note of how and what has changed.

- Assess the intensity of or possible modification to the lateral pull.

- It is also important that the test drives are made by the same person and along the same roads. It is best to drive along the road in both directions.

- Replacing a tyre with a new tyre does not necessarily guarantee that the pulling to one side will be eliminated. A selective interchanging of the tyres should first be carried out as described below.

- Where there is considerable difference in the tread depth of the tyres on the front axle in comparison with the tyres on the rear axle, the tyres with the better condition tread should always be fitted on the front axle.

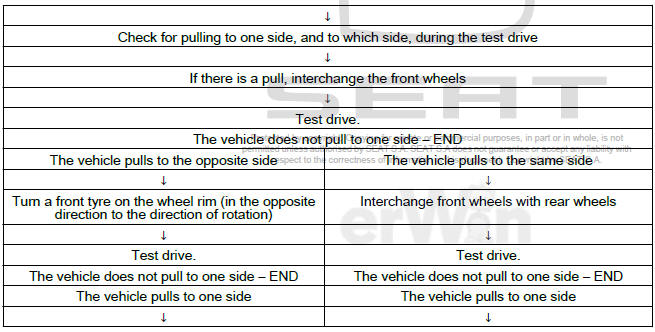

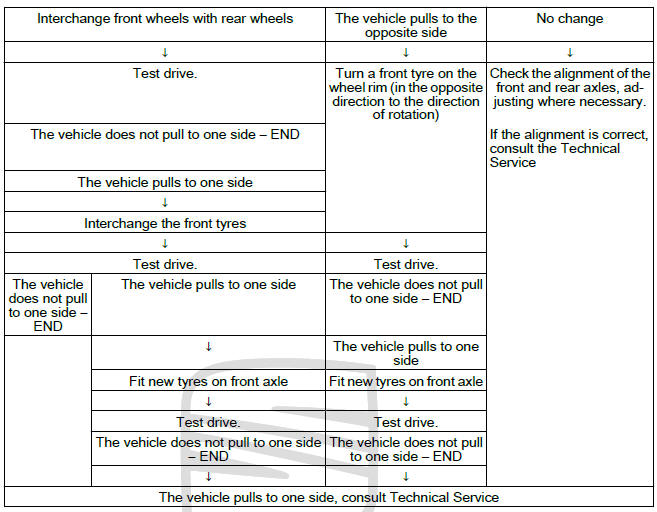

Selective interchange of wheels fitted with tyres without specified direction of travel.

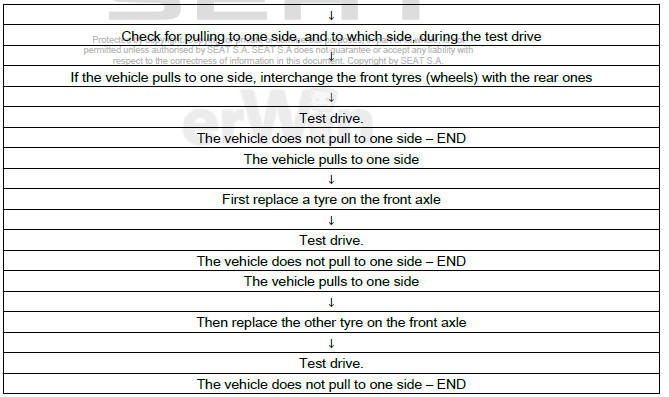

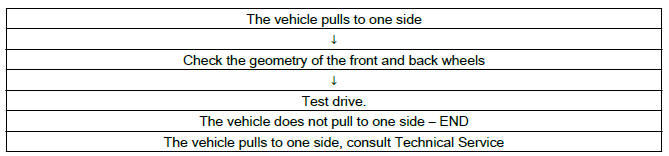

Selective interchange of wheels fitted with tyres with specified direction of travel.

Checking radial and lateral runout of

wheels and tyres

Checking radial and lateral runout of

wheels and tyres

Checking radial and lateral runout of

wheels and tyres, tolerances

Radial and lateral runout occur when the wheel and tyre do not

run absolutely true.

For technical reasons, 100% true running is ...

Adaptive cruise control

Adaptive cruise control

Calibrating adaptive cruise control

Calibrating Adaptive Cruise Control

(ACC)

Before calibrating the adaptive cruise control (ACC), it must be

ensured that the sensor, the retainers and the fixing ...

See also:

Removing and installing sliding sunroof

adjustment control unit - J245-

Removing

Note

If you must remove a defective engine while the panoramic window

is closed, please proceed as described.

Remove the cover of the roller blind.

Disconnect the electrical plug con ...