Seat Leon >> Raising wheel bearing to unladen position (vehicles with coil springs), front axle

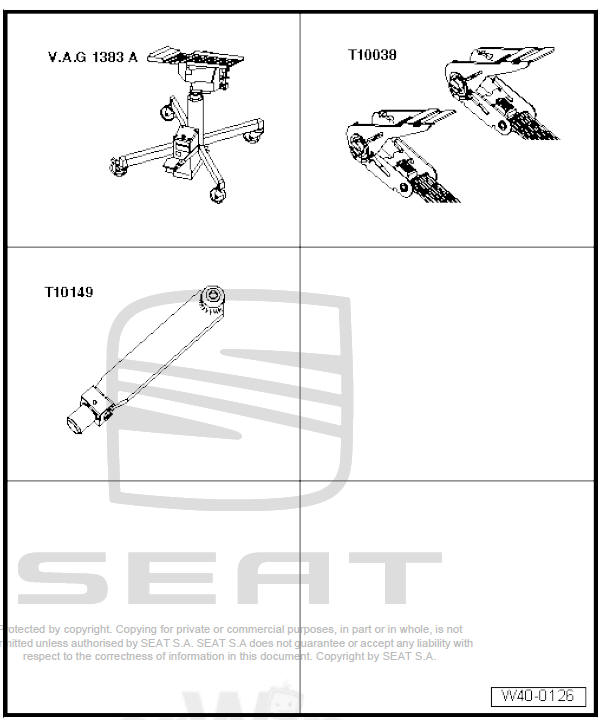

Special tools and workshop equipment required

- Engine elevator - V.A.G 1383 A-

- Support tool - T10038-

- Mounting - T10149-

| Caution All bolts on running gear components with bonded rubber bushes may be tightened only when the component is in the unladen position (normal position). Bonded rubber bushes can only be turned to a limited extent. Therefore, before tightening the bolts, suspension components with bonded rubber bushes must be brought into a position corresponding to the normal position of the unladen vehicle while driving (unladen position). The bonded rubber bushes are otherwise constantly tensioned and have a shorter service life. |

To simulate this position on the lifting platform, raise the respective wheel suspension with the engine and gearbox jack - V.A.G 1383 A- and support - T10149- .

Before raising wheel unit, secure vehicle to arms of lifting platform using tensioning straps - T10038- .

| WARNING If the vehicle is not strapped down, there is a great danger that the vehicle will slip off the lifting platform! |

- Turn wheel hub until one of the wheel bolt holes is at the top.

- Attach support - T10149- to wheel hub using wheel bolt.

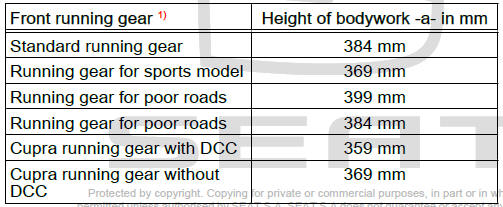

Respective nuts and bolts may be tightened only when dimension -a- between the centre of wheel hub and edge of wheel housing has been attained.

Note This measurement must be taken with the suspension in the unladen position (vehicle unladen).

The dimension -a- depends on the ride height of the installed running gear:

1) The running gear fitted to the vehicle is specified the vehicle data sheet. The running gear is identified by the PR number.

- Raise wheel bearing housing using the engine and gearbox jack - V.A.G 1383 A- until dimension -a- is attained.

WARNING

|

- Tighten respective nuts and bolts.

- Lower wheel bearing housing.

- Pull engine and gearbox jack - V.A.G 1383 A- out from under vehicle.

- Remove support - T10149- .

Raising wheel bearing to unladen position (vehicles with coil springs), rear

axle

Raising wheel bearing to unladen position (vehicles with coil springs), rear

axle

Special tools and workshop

equipment required

Engine elevator - V.A.G

1383 A-

Support tool - T10038-

Mounting - T10149-

CautionAll bolts on running gear components with bonded

...

See also:

Layout - telephone

Structure - Telephone, versions without control unit 1 for information

electronics

- J794-

- Mobile charging cradle -

R265-

Removal and installation

- Telephone microphone -

R3 ...