Seat Leon >> Coolant pump toothed belt: Check

SEAT Leon Service and Repair Manual / Maintenance / Description of work / Coolant pump toothed belt: Check

Remove the guard and check the toothed belt.

Install toothed belt guard.

| WARNING Applies only for petrol engines as they do not have a specified timing belt change interval. |

Remove the guard and check the toothed belt:

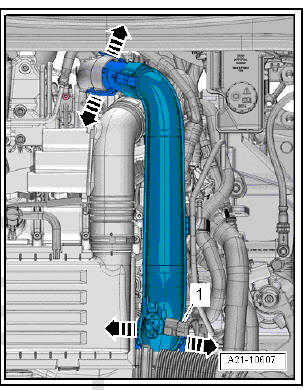

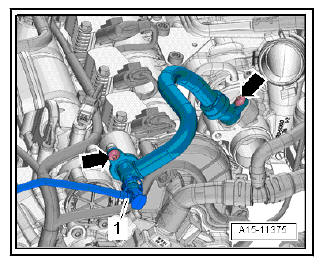

- Expose the air hoses on air pipe clear.

- Detach the connector -1-.

- Release connectors -arrows- and pull off the air pipe.

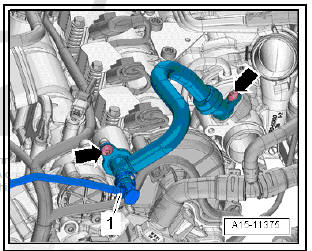

- Press release tabs and disconnect hose -1- for activated charcoal filter.

- Unscrew the bolts -arrows- and detach the hose for the crankcase breather hose.

- Expose the wiring harness -arrows-.

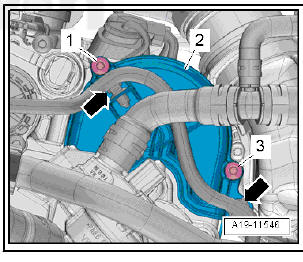

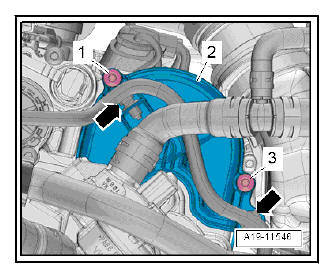

- Loosen the bolts -1 and 3- and remove the protective cover -2- of the coolant pump belt.

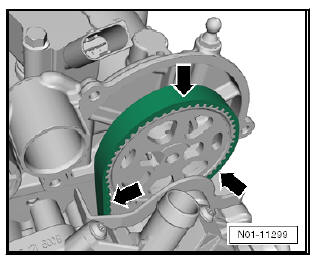

- Turn crankshaft by the bolt of the crankshaft toothed belt in the

direction of the engine and check the entire toothed belt for the

following:

- Cracks, cross-sectional breaks, cracks (coating) -arrow-

- Side contact

- Fraying of cord strands

- Cracks (in teeth base) -arrow-

- Layer separation (toothed belt body, draw strands)

- Surface cracks (synthetic coating)

- Traces of oil and grease

NOTICE If faults are found always renew toothed belt. This will avoid possible breakdowns or operating problems. The replacement of a toothed belt is a repair measure.

Install notched belt guard:

- Installation is carried out in reverse order. When installing, note the following:

- Tighten the bolts -1 and 3- to 8 Nm.

- Tighten the bolts -arrows- at 9 Nm.

Notched belt for camshaft drive: Check

Notched belt for camshaft drive: Check

Remove the top guard and check the toothed belt.

Install the top toothed belt guard.

WARNINGApplies only for petrol engines as they do not

have a specified

timing belt change interva ...

Poly-V belt: check condition

Poly-V belt: check condition

Carry out the following work:

Crank engine using vibration damper, using a socket spanner.

Check the Poly-V belt -1- with respect to:

Substructure cracks (cracks, core ruptures, cross section ...

See also:

Remove and install heat shield for luggage

compartment floor

Special tools and workshop equipment required

Torque wrench - V.A.G 1331-

Protective goggles and leather gloves

Removing

DANGER!

Always wear safety goggles and leather gloves ...