Seat Leon >> Adjusting camber at rear wheels

Adjusting camber on rear axle, torsion beam axle

Camber cannot be adjusted.

If the measurements are outside the permitted tolerances, check the axle beam for damage and renew if necessary.

Adjusting camber on rear axle, multi-link suspension

Special tools and workshop equipment required

- Torque wrenches - V.A.G 1332-

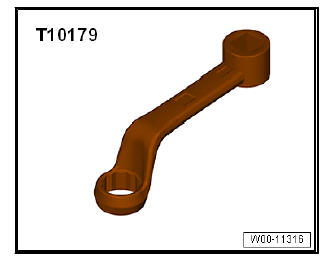

- Insert tool, 18 mm - T10179-

- Loosen upper transverse link nut -A- on subframe.

- Adjust camber by turning hexagon head of eccentric bolt -arrow-.

Note The maximum adjustment range is 90º to the left or right of the centre position.

- Tighten nut -A-.

- To do so, use insert tool - T10179- .

On use of insert tool - T10179- , tighten nuts to 80 Nm.

- Check camber value again after nut -A- has been tightened.

- Check camber value again after tightening nut -A-

Adjusting toe setting at rear wheels

Adjusting toe setting at the rear wheels, vehicle with torsion beam axle

The convergence of the rear axle cannot be adjusted.

If the measurements are outside the permitted tolerances, check the axle beam for damage and renew if necessary.

Adjusting toe on rear axle, multi-link suspension

Special tools and workshop equipment required

- Torque wrenches - V.A.G 1332-

- Loosen nut -1-.

- Turn eccentric bolt -2- until specification is attained.

Note The maximum adjustment range is 90º to the left or right of the centre position.

- Tighten nut -1-.

- Check toe setting once again after tightening nut -A-

Front axle camber: correction

Front axle camber: correction

Special tools and workshop equipment required

Torque wrenches - V.A.G 1332-

Note

Camber correction is necessary only after body repairs. Camber

cannot be adjusted. It can be determined ...

Adjusting front axle convergence

Adjusting front axle convergence

Special tools and workshop equipment required

Torque wrenches - V.A.G 1332-

Insert tool - V.A.G 1332/9-

Counterhold track rod ball joint -1- with spanner when loosening

and tight ...

See also:

General notes on brake fluid

Note

Always use fresh brake fluid.

In case of brake fluid spillage, rinse with a copious amount of

water.

DANGER!

Before performing the first test drive, make sure that the brakes ...