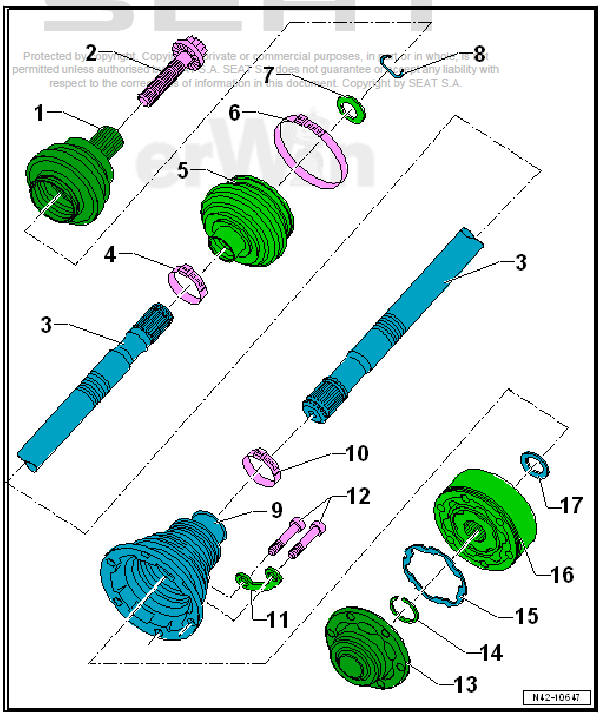

Seat Leon >> Assembly overview - drive shaft

SEAT Leon Service and Repair Manual / Running gear, axles, steering / Rear suspension / Drive shaft / Assembly overview - drive shaft

- - Outer constant velocity joint

- Always replace completely

- Removing

- Installing: drive ontoshaft as far as stop usingplastic hammer

- Distribute grease fillingevenly in joint

- Checking

- - Bolt

- Always renew after removing

- Before securing, cleanthe threads in the CVjoint using a thread tap

- 200 Nm +180º

- - Drive shaft

- Assignment

- - Clamp

- Always renew after removing

- Tightening

- - Dust guard

- Check for splits andchafing

- Material: Hytrel (Polyelastomer)

- - Clamp

- Always renew after removing

- Tightening

- - Dished spring

- With internal groove

- Installation position

- - Securing ring

- Always renew after removing

- Insert in groove in shaft

- - Dustguard for constant velocity joint

- Material: Hytrel (Polyelastomer)

- Without breather hole

- Check for splits and chafing

- Drive off constant velocity joint with a drift

- Coat sealing surface of constant velocity joint with -D 454 300 A2- before installing.

- - Clamp

- Always renew after removing

- Tightening

- - Locking plate

- - Internal splined bolt

- Always renew after removing

- Pre-tighten diagonally to 10 Nm and then tighten completely diagonally to the respective tightening torque.

- 40 Nm

- - Cover

- Always renew after removing

- Always renew

- Pressing off

- - Securing ring

- Always renew after removing

- Remove and install with circlip pliers - VW 161 A-

- - Seal

- Always renew after removing

- The surface that is attached to the constant velocity joint should be free of grease and oil

- - Inner constant velocity joint

- Always replace completely

- Distribute grease filling evenly in joint

- Pressing off

- Insertion

- Checking

- - Dished spring

- With internal groove

- Installation position

Drive shaft

Drive shaft

...

Removing and installing drive shaft

Removing and installing drive shaft

Special tools and workshop equipment required

Torque wrenches - V.A.G 1332-

Puller - T10520-

CautionWhen removing and installing drive shafts, do

not allow them

to hang ...

See also:

Repair notes

Repair work on refrigerant circuit which

may only be performed in appropriate

workshops by specially trained mechanics

Repair work on refrigerant circuit which

may be performed only in appropriate ...