Seat Leon >> Exploded view - control unit and hydraulic unit

SEAT Leon Service and Repair Manual / Brake system / Anti-lock brake system / Control unit and hydraulic unit / Exploded view - control unit and hydraulic

unit

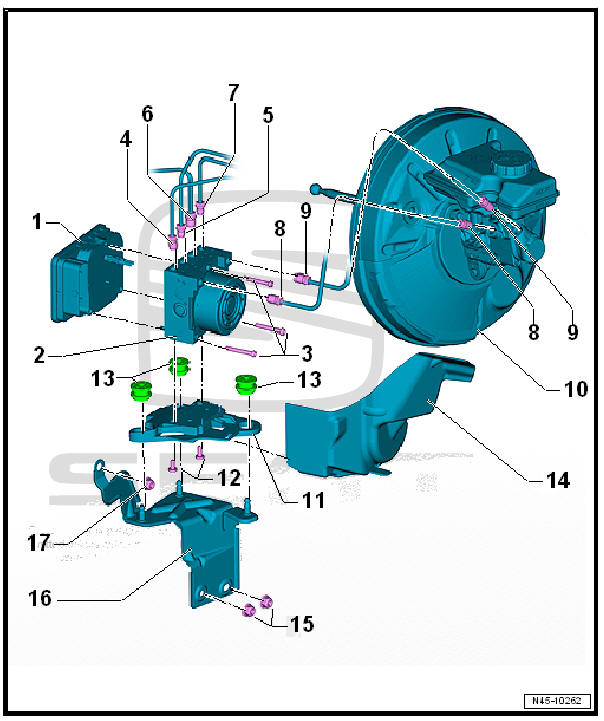

Exploded view - control unit and hydraulic unit, LHD

- - ABS control unit - J104-

- Do not unplug connector before completing self-diagnosis

- Switch off ignition before detaching connector

- - ABS hydraulic unit - N55-

- - Torx bolt

- Tighten the new Torx screws alternately in two stages:

- Stage 1: initial tightening torque: 1 Nm with 1.5 Nm (to allow the seal to settle)

- Stage 2: final specified torque: 2.5 Nm

- - Brake pipe

- To the rear right brake calliper

- Markings: Ø 5.25 mm and union nut with thread M 12 x 1

- 14 Nm

- - Brake pipe

- To front left brake caliper.

- Markings: Ø 5.25 mm and union nut with thread M 10 x 1

- 14 Nm

- - Brake pipe

- To front right brake caliper.

- Markings: Ø 5.25 mm and union nut with thread M 12 x 1

- 14 Nm

- - Brake pipe

- To the rear left brake calliper

- Markings: Ø 5.25 mm and union nut with thread M 10 x 1

- 14 Nm

- - Brake pipe

- Master brake cylinder / pressure-rod piston circuit to hydraulic unit

- Markings: Ø 6 mm and union nut with short thread M 12 x 1

- 14 Nm

- - Brake pipe

- From secondary piston circuit of brake master cylinder to hydraulic unit.

- Markings: Ø 6 mm and union nut with short thread M 12 x 1

- 14 Nm

- - Brake servo unit

- - Support

- - Torx bolt

- 8 Nm

- - Rubber damper

- 3 off

- - Heat shield

- Assignment - Electronic parts catalogue

- - Hexagonal nut

- 20 Nm

- - Support

- - Hexagonal nut

- 20 Nm

WARNING

Do not bend the brake lines.

Any damaged brake lines must be renewed.

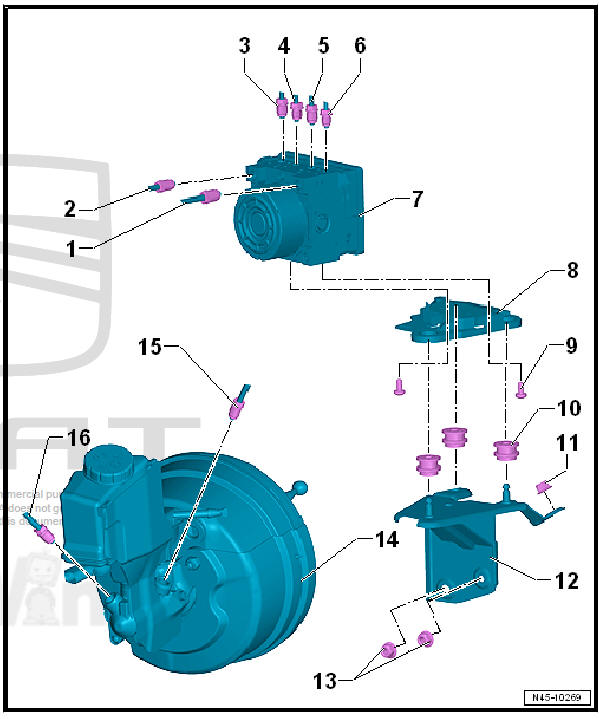

Exploded view - control unit and hydraulic unit, RHD

- - Brake pipe

- From secondary piston circuit of brake master cylinder to hydraulic unit.

- Markings: Ø 6 mm and union nut with short thread M 12 x 1

- 14 Nm

- - Brake pipe

- Master brake cylinder / pressure-rod piston circuit to hydraulic unit

- Markings: Ø 6 mm and union nut with short thread M 12 x 1

- 14 Nm

- - Brake pipe

- To the rear right brake calliper

- Markings: Ø 5.25 mm and union nut with thread M 12 x 1

- 14 Nm

- - Brake pipe

- To front left brake caliper.

- Markings: Ø 5.25 mm and union nut with thread M 10 x 1

- 14 Nm

- - Brake pipe

- To front right brake caliper.

- Markings: Ø 5.25 mm and union nut with thread M 12 x 1

- 14 Nm

- - Brake pipe

- To the rear left brake calliper

- Markings: Ø 5.25 mm and union nut with thread M 10 x 1

- 14 Nm

- - ABS hydraulic unit - N55- with ABS control unit - J104-

- - Support

- Check for secure seating after installing

- - Bolt

- 2 off

- 8 Nm

- - Rubber damper

- 3 off

WARNING

When installing the bracket, ensure that the rubber dampers are not pressed out of the console.

After installation, check that the ABS hydraulic unit - N55- is firmly seated, or malfunction can occur.

- - Nut

- 20 Nm

- - Support

- - Nut

- 2 off

- 20 Nm

- - Brake servo and brake master cylinder

- - Brake pipe

- Master brake cylinder / pressure-rod piston circuit to hydraulic unit

- Markings: Ø 6 mm and union nut with short thread M 12 x 1

- 14 Nm

- - Brake pipe

- From secondary piston circuit of brake master cylinder to hydraulic unit.

- Markings: Ø 6 mm and union nut with short thread M 12 x 1

- 14 Nm

Removing and installing ABS control

unit - J104- / ABS hydraulic unit - N55-

Removing and installing ABS control

unit - J104- / ABS hydraulic unit - N55-

Removing and installing ABS control

unit - J104- / ABS hydraulic unit - N55- ,

left hand steering

Special tools and workshop

equipment required

Torque wrenches -

V.A.G 1331-

Torque w ...

See also:

Model badges and brand emblems

Exploded view - Model badges and brand emblems

- Company emblem at front

Fitted to top grilled on

bumper trim panel

Secured to top grille on

bumper trim panel with

retaining clips ...