Seat Leon >> Lowering rear axle

Lowering rear axle, multi-link suspension, front-wheel drive

Special tools and workshop equipment required

- attachment tool - 3301-

- attachment tool - 3346-

- Torque wrenches - V.A.G 1332-

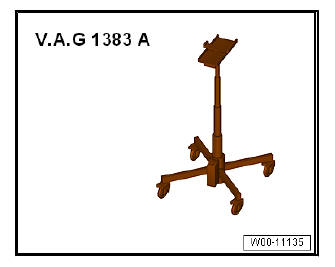

- Engine/gearbox jack - V.A.G 1383 A-

Lower subframe with attachments.

- Remove rear wheels.

- Unbolt brake calipers on both sides of vehicle and suspend from body.

- Remove the coil springs.

- Remove rear silencer for exhaust system.

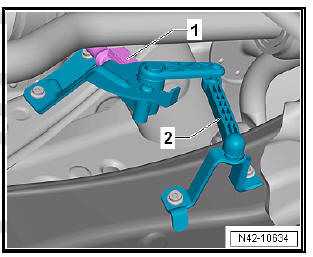

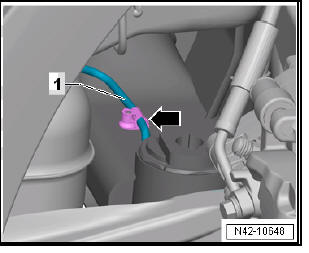

Vehicles with vehicle level senders

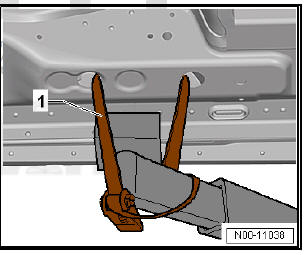

- Unplug the electrical connector -1-.

Continuation for all models:

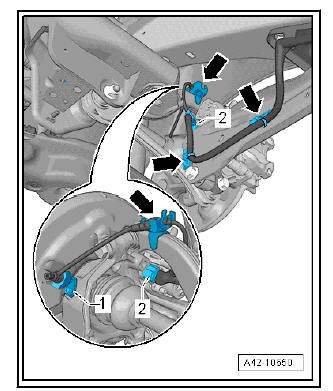

- Unplug electrical connector -1- from ABS speed sensor on both sides and move clear.

- Disconnect the electrical connector -2-right and left of the engine of the electromechanical parking brake on the brake caliper.

- Detach electrical wiring harness from retainers -arrows- and move clear.

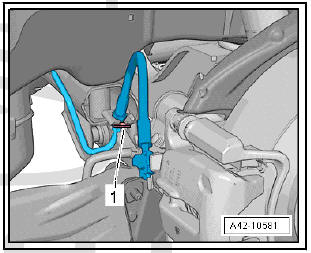

- Pull out retaining clip -1- on both sides of vehicle.

- Move brake line clear of retainer.

Note Do not open brake line.

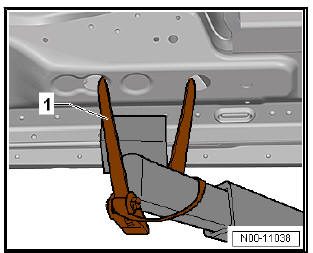

- Use tensioning straps - T10038- to strap vehicle to support beams of lifting platform on both sides.

| WARNING If the vehicle is not strapped down, there is a great danger that the vehicle will slip off the lifting platform. |

- Fix subframe at both forward bolts.

- Unscrew rear right bolt of subframe -arrow-.

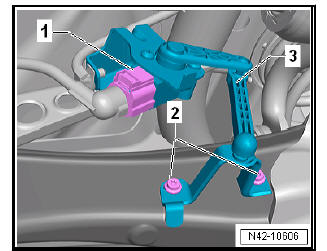

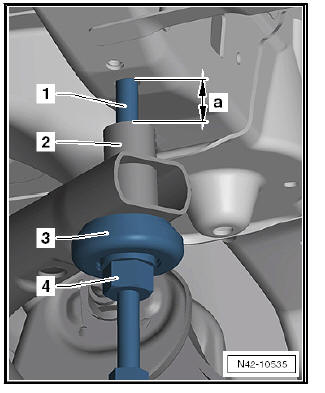

- Screw spindle - 3346/2- into thread of longitudinal member using thrust piece of assembly tool - 3301- and nut - 3346/3- .

- -3346/2- Spindle

- Sub-frame

- Thrust piece from assembly tool - 3301-

- Nut -3346/3-

- Unscrew rear left bolt of subframe.

- Turn nut -3346/3- on spindle -3346/2- until subframe is lowered by -a- = 40 mm.

Installing subframe with attachments

Carry out installation in the reverse sequence, noting the following:

Specified torques

- Exhaust pipes double clamp.

- On vehicles with vehicle level sender, carry out basic settings for wheel damper electronics

- On vehicles with vehicle level sender, carry out basic adjustment of headlights

Lowering rear axle, multi-link suspension, four-wheel drive

Special tools and workshop equipment required

- Torque wrenches - V.A.G 1332-

- Engine/gearbox jack - V.A.G 1383 A-

Lower subframe with attachments.

- Remove rear wheels.

- Unbolt brake calipers on both sides of vehicle and suspend from body.

- Remove the coil springs .

- Remove rear silencer for exhaust system.

Vehicles with vehicle level senders

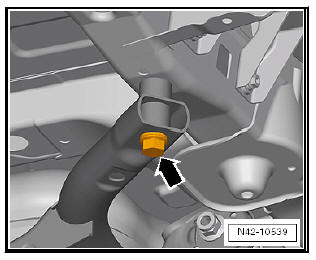

- Disconnect connector -1- from vehicle level sender -2-.

Continuation for all models:

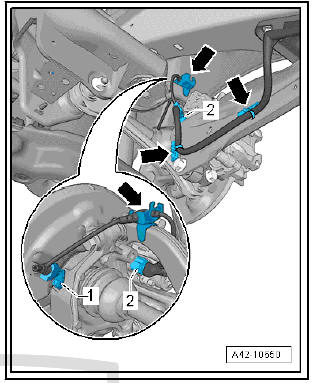

- Unplug electrical connector -1- from ABS speed sensor on both sides and move clear.

- Disconnect the electrical connector -2-right and left of the engine of the electromechanical parking brake on the brake caliper.

- Detach electrical wiring harness from retainers -arrows- and move clear.

- Pull out retaining clip -1- on both sides of vehicle.

- Move brake line clear of retainer.

Note Do not open brake line.

- Detach propshaft from rear final drive and secure.

- Use tensioning straps - T10038- to strap vehicle to support beams of lifting platform on both sides.

| WARNING If the vehicle is not strapped down, there is a great danger that the vehicle will slip off the lifting platform! |

- Locate subframe in position.

- Lower subframe with attachments about 20 mm.

- Separate connector on Haldex coupling above final drive.

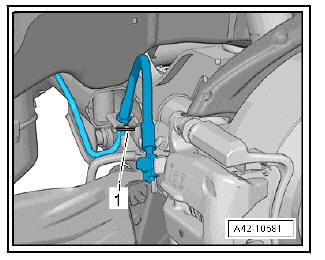

- Unclip brake line -1- from clip -arrow- on left side.

Note The clip will be destroyed and must be renewed.

- Lower subframe with attachments about 140 m

Installing subframe with attachments

Carry out installation in the reverse sequence, noting the following:

Specified torques

- Exhaust pipes double clamp.

- Propshaft.

- On vehicles with vehicle level sender, carry out basic settings for wheel damper electronics - Vehicle diagnostic tester.

- On vehicles with vehicle level sender, carry out basic adjustment of headlights.

- When does wheel alignment have to be checked?

Rear axle

Rear axle

Overview - rear axle

Overview - rear axle, torsion beam axle

Overview - rear axle, multi-link suspension

Overview - rear axle, multi-link suspension, four-wheel drive

...

Removing and installing rear axle

Removing and installing rear axle

Removing and installing rear axle, torsion

beam axle

Special tools and workshop equipment required

Support tool - T10038-

Torque wrenches - V.A.G 1332-

Engine/gearbox jack - VAS ...

See also:

Automatic car washes

The paint is so durable that the car can normally be washed without problems

in an automatic car wash. However, the effect on the paint depends to a large

extent on the design of the car wash, the b ...