Seat Leon >> Sealing rings

SEAT Leon Service and Repair Manual / 5-speed manual gearbox 0AH / Final drive - differential / Sealing rings

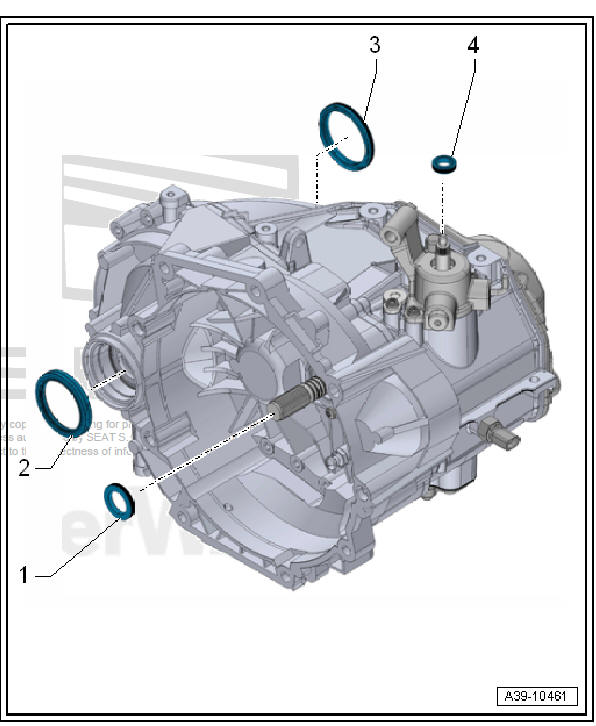

Location overview - seals

- - Oil seal

- For the input shaft

- Replace after removal

- - Oil seal

- For right flange shaft

- Replace after removal

- - Oil seal

- For left flange shaft

- Replace after removal

- - Oil seal

- For the gear selection shaft

- Replace after removal

Renewing left oil seal

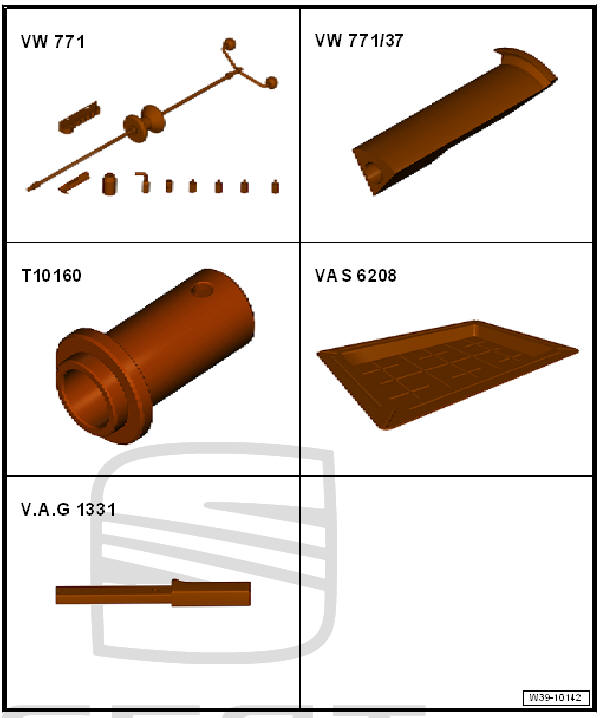

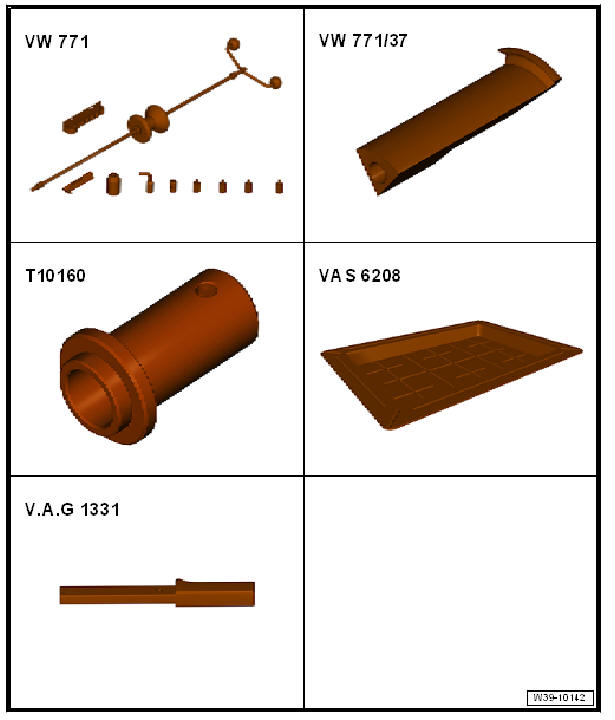

Special tools and workshop equipment required

- Universal tool - VW 771-

- Puller hooks - VW 771/37-

- Thrust pad - T10160-

- Tray - V.A.G 1306-

- or drip tray for workshop hoist - VAS 6208-

- Torque wrenches - V.A.G 1331-

- Sealing grease

- For grease allocation, refer to - Electronic parts catalogue (ETKA) .

Removing

- Remove the left hand side wheel.

- Remove noise insulation .

- Turn the steering toward the left.

- Remove drive shaft from flange shaft .

- Raise drive shafts as high as possible and secure, taking care not to damage surfaces.

- Place drip tray under gearbox.

- Extract the bolt fastening the flanged shaft. To do so, thread 2 bolts on the flange and lock the shaft using the assembly lever.

- Remove flanged shaft together with compression spring.

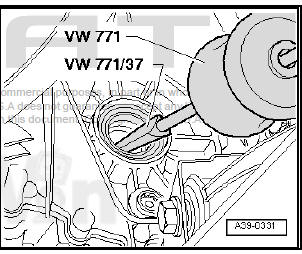

- Remove the flanged shaft seal with the universal tool - VW 771- and the extraction hook - VW 771/37- .

Installing

- Drive in new seal to stop, being careful not to cant seal.

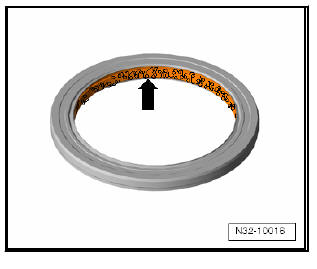

- Fill space between sealing lip and dust lip -arrow- with sealing grease .

- Insert flange shaft.

- Secure flange shaft with countersunk bolt and tighten to 25 Nm.

- Install drive shaft to flange shaft .

- Check gear oil level and top up to lower edge of oil filler hole if necessary .

- Install the lower part of the front left wheel housing liner.

- Install noise insulation .

Specified torques

- Flange shaft to gearbox

Renewing right oil seal

Special tools and workshop equipment required

- Universal tool - VW 771-

- Puller hooks - VW 771/37-

- Thrust pad - T10160-

- Tray - V.A.G 1306-

- or drip tray for workshop hoist - VAS 6208-

- Torque wrenches - V.A.G 1331-

- Sealing grease

- For grease allocation, refer to - Electronic parts catalogue (ETKA) .

Removing

- Remove noise insulation .

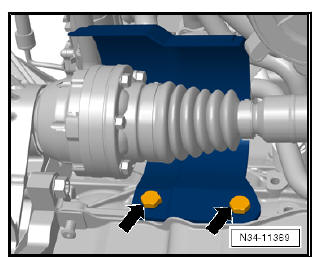

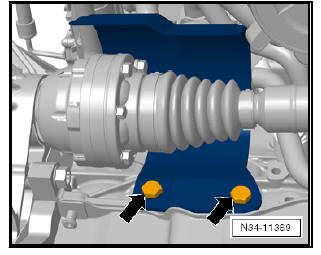

- If present, remove the heat shield -arrows- of the drive shaft.

- Remove drive shaft -1- from flange shaft .

- Raise drive shaft as high as possible and secure, taking care not to damage surfaces.

- Place drip tray under gearbox.

- Extract the bolt fastening the flanged shaft. To do so, thread 2 bolts on the flange and lock the shaft using the assembly lever.

- Remove flanged shaft together with compression spring. If necessary, remove engine/gearbox connecting bolt in area of flange shaft.

- Pull out flange shaft oil seal using multi-purpose tool - VW 771- and puller hooks - VW 771/37- or prise out using a lever.

Installing

- Drive in new seal to stop, being careful not to cant seal.

- Half-fill space between sealing lip and dust lip with sealing grease .

- Insert flange shaft.

- Secure flange shaft with countersunk bolt and tighten to 25 Nm.

- Install drive shaft to flange shaft.

- Install heat shield for drive shaft, if present -arrows- .

- Check gear oil level and top up to lower edge of oil filler hole if necessary.

- Install noise insulation .

Specified torques

- Flange shaft to gearbox

Differential

Differential

...

See also:

Self-adhesive, side emblems (3 and 5-

door models): replacing

Company badge "ITECH"

Special tools and workshop

equipment required

Hot-air blower - SAT 1416-

Digital thermometer - SAT

4013-

Thrust piece - T20098-

Release lever - U 30800-

Adhesive ...